Advantages of Plastic Optical Fiber

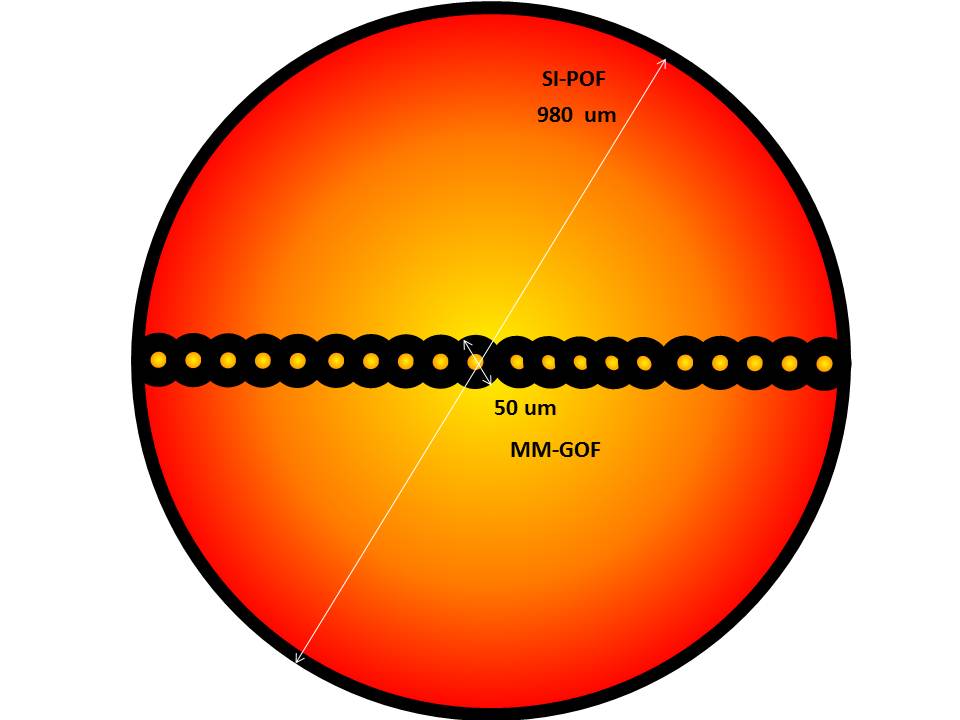

Plastic Optical Fiber (POF) is a unique member of the optical fiber family. POF is made of Poly Methyl Methacrylate (PMMA), with a large core diameter (~1 mm) and high numerical aperture (NA 0.3 – 0.5). The figure shows a comparison of a typical POF geometry compared to another well-known optical fiber, the Multi-Mode Glass Optical Fiber (MM-GOF). It is easy to appreciate the huge core diameter (20x) as well as the relatively thin clad of POF compared to MM-GOF.

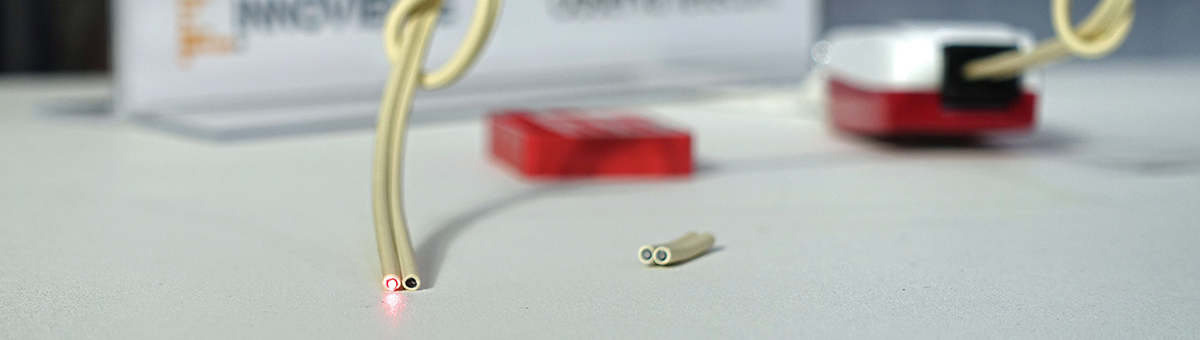

Thanks to its huge core diameter, POF is immune to misalignments and strong vibrations, and can be installed in rugged industrial and automotive environments without any loss of communication capacity. POF is ideally suited for deployment either by a professional installer or a do-it-yourself installer using basic tools, such as a pair of scissors or a cutter, and inexpensive plastic connectors.

As optical transmission media, POF is completely immune to electrical noise. For example, existing copper wire installations will not interfere with data passing through POF lines, so POF can be installed anywhere next to electrical cabling. POF and its connectors and optoelectronics are low cost consumer parts that enable installers to save on cable costs and installation, as well as testing and maintenance time.

Widely used in over 20 million cars for infotainment networks, POF is part of the automotive standard MOST® (Media Oriented Systems Transport) for high-speed data transmission in car networks.

POF Technology

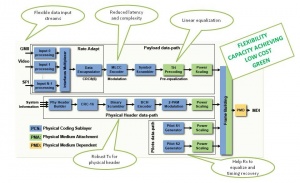

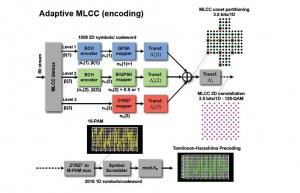

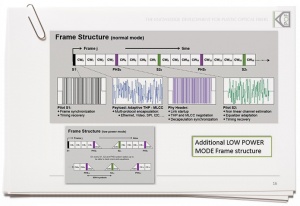

KDPOF has developed a high spectral efficiency communication technology that exploits the available capacity of large core Plastic Optical Fiber (POF). This technology uniquely approaches the available communication capacity, delivering a transmission system that automatically adapts its operation (bit-rate and equalization) to variable operating conditions like temperature, fiber, bending, coupling losses, connector aging, etc. As POF is closer to copper or air than to glass optical fiber as a transmission media, we use techniques similar to those implemented in copper and wireless communication systems to approach the maximum theoretical capacity limit of the fiber.

Advantages of our Technology Include

Channel Capacity: Closest approach to the theoretical maximum capacity of the channel (Shannon limit)

Implementation: Reduced area and power consumption due to efficient implementation

Adaptive Bit Rate: Flexible, “on-the-fly” adaptation to channel variations and application requirements

Self-diagnostics: Deep self-diagnostic capability to monitor channel state and performance

Interfaces: Data interfaces customized for each market application

Energy Efficiency: Energy efficient Ethernet with a higher performance compared to standard Gigabit Ethernet applications

For further details, please download the white paper:

Optoelectronics

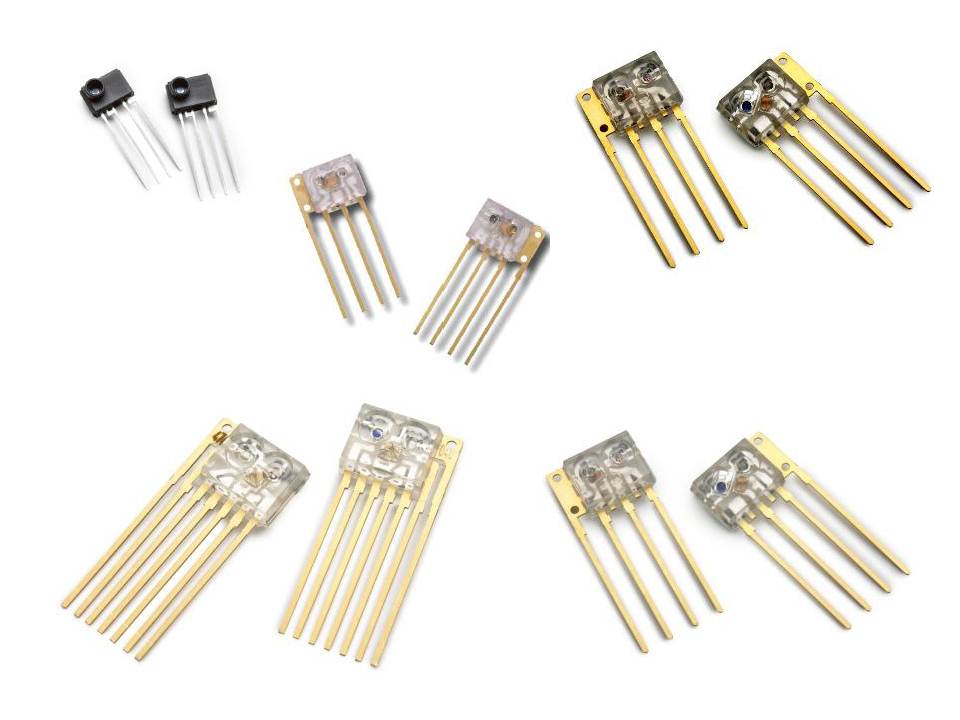

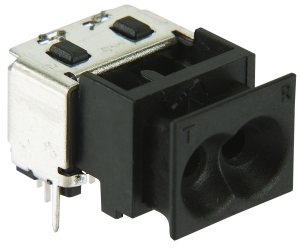

KDPOF’s approach to a low-cost and highly efficient communication system over standard SI-POF has been to reuse currently market available optoelectronic devices as much as possible. The result has been a PHY that can operate with current low-cost, high volume light sources (red LEDs) and photodiodes used in POF installations.

Traditionally, gigabit-class fiber optic transceivers are based on 850 nm and higher wavelength light sources, precision mounted on complex optical assemblies, which couple into 200 micron and smaller core glass optical fibers. KDPOF’s compatible gigabit-class transceivers utilize eye-safe, visible 650 nm (red) LEDs packaged in a transparent plastic moulded package with integrated lenses for easy coupling into 1 mm core POF.

Gigabit Transceivers

Gigabit optical transceivers optimized for operation with Gigabit POF standard PHYs like KDPOF’s are available from leading optoelectronic companies such as Firecomms and Yazaki. Only using these transceivers with KDPOF semiconductors would yield the optimum performance described.

Performance

KDPOF’s technology outperforms the state of the art currently available in the market. Depending on the requirements and restrictions of each target market, KDPOF’s technology adapts its behavior to deliver the highest level of performance.

In the Automotive industry, next generation Infotainment and ADAS vehicle networks demand at least 1 Gb/s for 15 meters, but with a challenging link power budget. KDPOF’s technology is the only available technology that meets the stringent automotive requirements. In the Home & SOHO market, KDPOF standard-based solution delivers 1 Gb/s over a maximum of 50 meters. Finally, Industrial networks add the demand for lower bitrates (100 Mb(s) but longer distances). Current industry standards specify a maximum coverage of 50 meters. Now, thanks to KDPOF’s technology, industry standards can be reviewed to increase the POF based networks coverage up to 150 meters at 100 Mb/s.

Standardization

KDPOF technology is being used as the basis for technical standards developed by key European standards organization:

ETSI

The European Telecommunications Standards Institute (ETSI) published in 2015 a new technical standard, which uses KDPOF technology as the reference for Europe-wide Gigabit POF installations.

ETSI TS 105 175-1 (v2.0.0)

ETSI TS 105-175-1-1 (v1.1.1)

ETSI TS 105 175-1-2 (v1.1.1)

IEEE

IEEE 802.3bv published the standard 1000BASE-RH as an amendment to 802.3 set of Ethernet specification.

Optical Multi-Gigabit Ethernet in the car is on the verge of standardization and implementation. With the approval of the IEEE 802.3 working group, a team of individuals affiliated with more than 15 key carmakers and components suppliers, including KDPOF, has started the standardization of an IEEE 802.3 Automotive Optical Multi-Gigabit Standard with strong support from the industry. The first prototypes are projected by the end of 2021.

For details, please see the white paper:

ISO

ISO (International Organization for Standardization) standardizes in-vehicle Ethernet with the series 21111. Several key components assure reliable implementations of systems that realize optical connectivity with 1 Gb/s as a physical layer.

ISO 21111-3:2020 specifies additional features to IEEE 802.3bv, such as wake-up and synchronized link sleep algorithms. It also contains a complete conformance test plan for IC providers that implement this standard.

ISO 21111-5:2020 specifies requirements at the system level and a complete conformance and interoperability test plan for ECU providers that implement optical 1 Gb/s physical layer as specified in ISO 21111-3.

Further relevant parts of ISO 21111 for this type of high speed in-vehicle communications include:

- ISO 21111-1 provides general definitions.

- ISO 21111-2 defines general wake-up and sleep definitions and RGMII specifications.

- ISO 21111-4:2020 is devoted to optical connectivity component specification and tests.